Our products are ISO 9001-2008 certified. Hence, our products are safe, superior, and reliable.

Read MoreDevelopment

We have a dedicated and qualified team of experts who design unique and easy-to-use industrial pumps.

Read MoreWe have a professional team with expertise in their respective team. We complete our order as per demand and on time always.

Read MoreIndustrial Pump, Centrifugal Pump Manufacturer

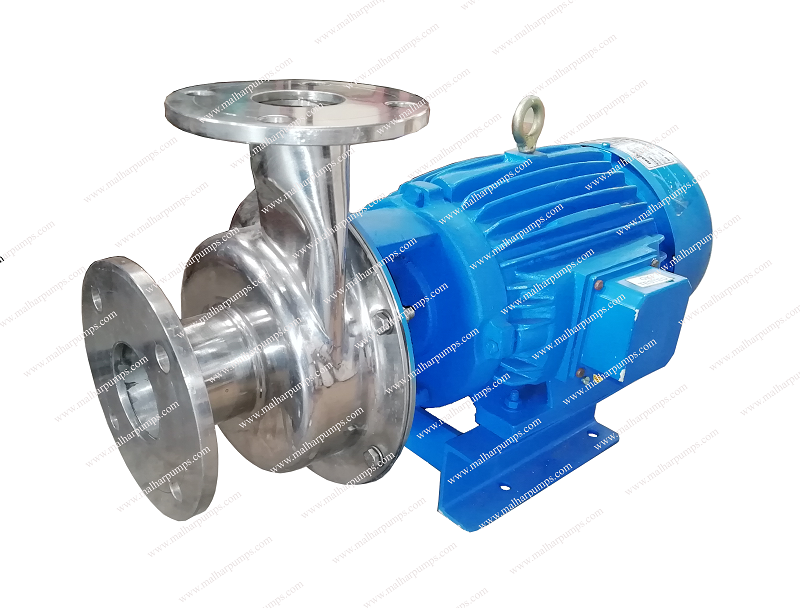

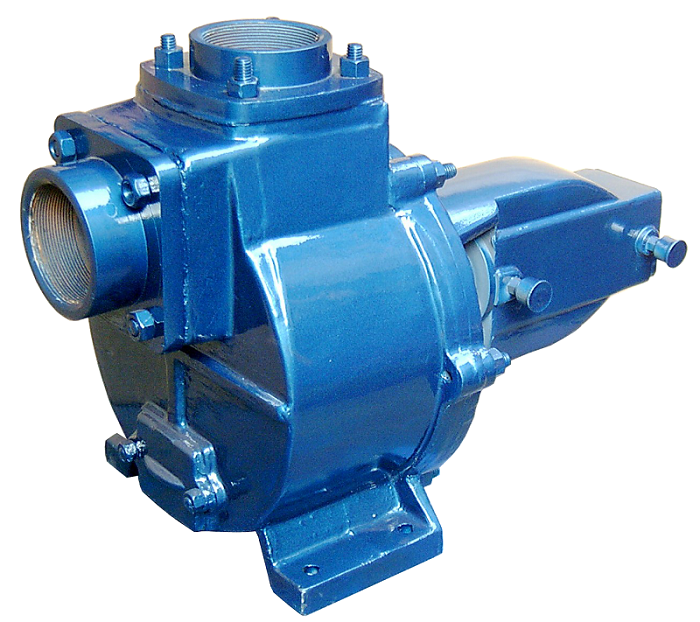

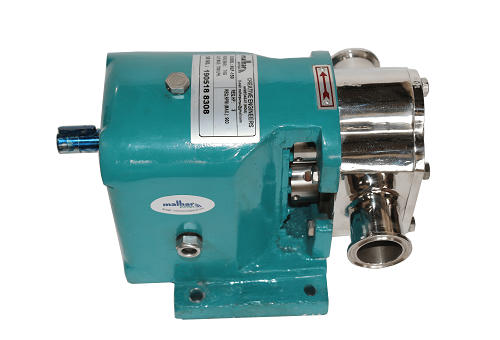

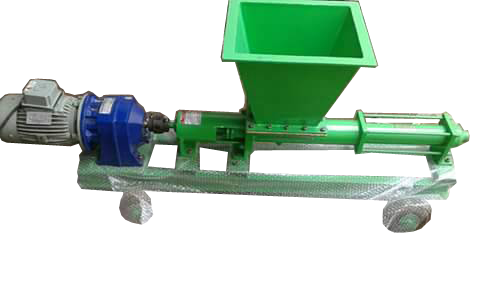

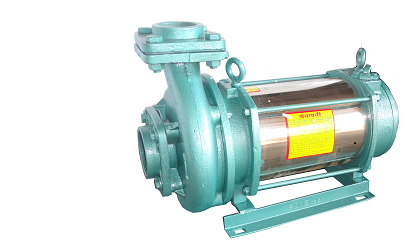

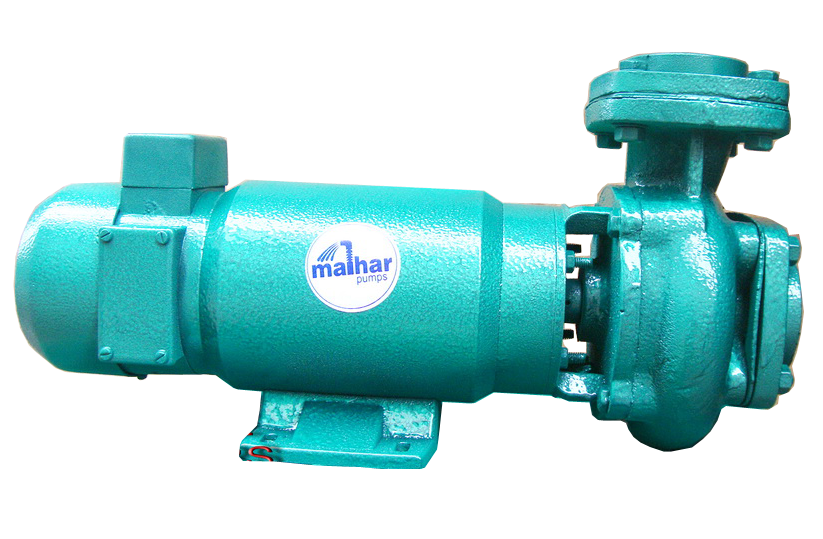

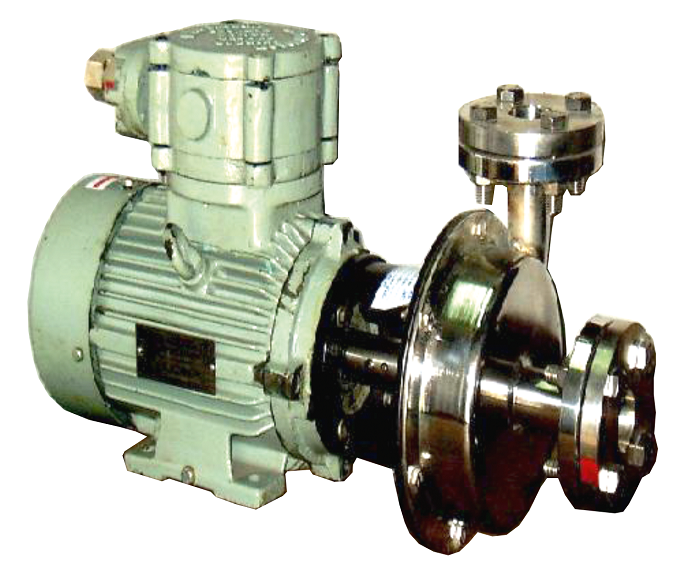

Creative Engineers are Leading Manufacture, Supplier and Exporting a wide range of Flexible Shaft Driven Pump, Rubber Lined Pump, Sewage & Dewatering Submersible Pump, Flameproof Pump, SS Self Priming Pump, Glandless Pump, Inline Centrifugal Pump, Thermic Fluid Pump, Barrel Pump, Sealless Pump, Screw Pump, Sump Pump, Stainless Steel Pump, Barrel Drum Pump, Floating Pump, DC Pumps, Hydraulic Test Pump, Back Pull Out Pump, Self Priming Centrifugal Pump, Fuel Transfer Pump, External Gear Pump, Chemical Pump, Split Casing Pump, Gear Pump, Rotary Gear Pump, Lobe Pump, Water Meter, Pressure Differential Meter, Electromagnetic Flow Meter, Mass Flow Meter, Vortex Flow Meter, Mud Pump, Submersible Pump, Solar Pump, Fire Fighting Pump, High Pressure Plunger Pump, Dosing Systems, Metering Pump, Air Operated Double Diaphragm Pump and Centrifugal Pump

Having 23 Years of Experience

Year of Establishment 2001, Creative Engineers is an offshoot of more than two decade old renowned group “Fair Deal”. Under the able proprietorship of Mr. Gaurang Shah who is a B.E. (Mechanical), the company has grown by leaps and bounds. Our's is an ISO-9001:2008 certified organization engaged in manufacturing, trading, importing and exporting different types of industrial and chemical pumps like horizontal centrifugal pumps, multistage centrifugal pumps, submersible pumps, agricultural water pumps, submersible water pumps, electric motors and impellers which have found applications in different industries like pharmaceutical, chemical, agricultural and irrigation.

Serving Impressive List Of Long Term Clients!

Our Worldwide Presence Ensures Timeliness, Cost Efficiency and Compliance Adherence Required to Ensure Your Timelines Are Met. Serving with Experience and Expertise in Multiple Industries, as One of the World'S Leading Pumps Manufacturer.